When it comes to tackling the most demanding cleaning tasks in commercial and industrial settings, an 8 GPM pressure washer stands as the ultimate powerhouse solution. These high-flow rate machines deliver exceptional cleaning performance that far exceeds standard residential units, making them indispensable for contractors, fleet maintenance operations, and large-scale cleaning projects. Understanding the capabilities and applications of 8 gallon per minute pressure washers can transform how you approach challenging cleaning tasks, dramatically reducing both time and labor costs while achieving superior results.

The significance of flow rate in pressure washing cannot be overstated, and 8 GPM units represent the sweet spot between power and practicality for many professional applications. Unlike lower-flow machines that rely primarily on pressure to break down dirt and grime, high GPM pressure washers leverage substantial water volume to flush away debris efficiently. This combination of adequate pressure with high flow creates a cleaning dynamic that’s particularly effective for large surface areas, heavy soil conditions, and applications where rapid cleaning is essential for operational efficiency.

Understanding 8 GPM Pressure Washer Specifications

The technical specifications of an 8 gallon per minute pressure washer reveal why these machines excel in demanding environments. Most 8 GPM units operate within the 2,500 to 4,000 PSI range, creating cleaning units (CU) that typically fall between 20,000 and 32,000. This cleaning unit calculation, derived by multiplying PSI by GPM, provides a standardized measure of overall cleaning power that helps professionals select appropriate equipment for specific applications.

Key Specifications for 8 GPM Pressure Washers:

Suggested read: NorthStar Power Washer: Professional Cleaning Performance You Can Trust

- Flow Rate: 8.0 gallons per minute

- Pressure Range: 2,500-4,000 PSI typically

- Cleaning Units: 20,000-32,000 CU

- Engine Requirements: 24-35 HP gas engines or electric equivalents

- Water Temperature: Cold water standard, hot water options available

- Pump Type: Usually triplex plunger pumps for durability

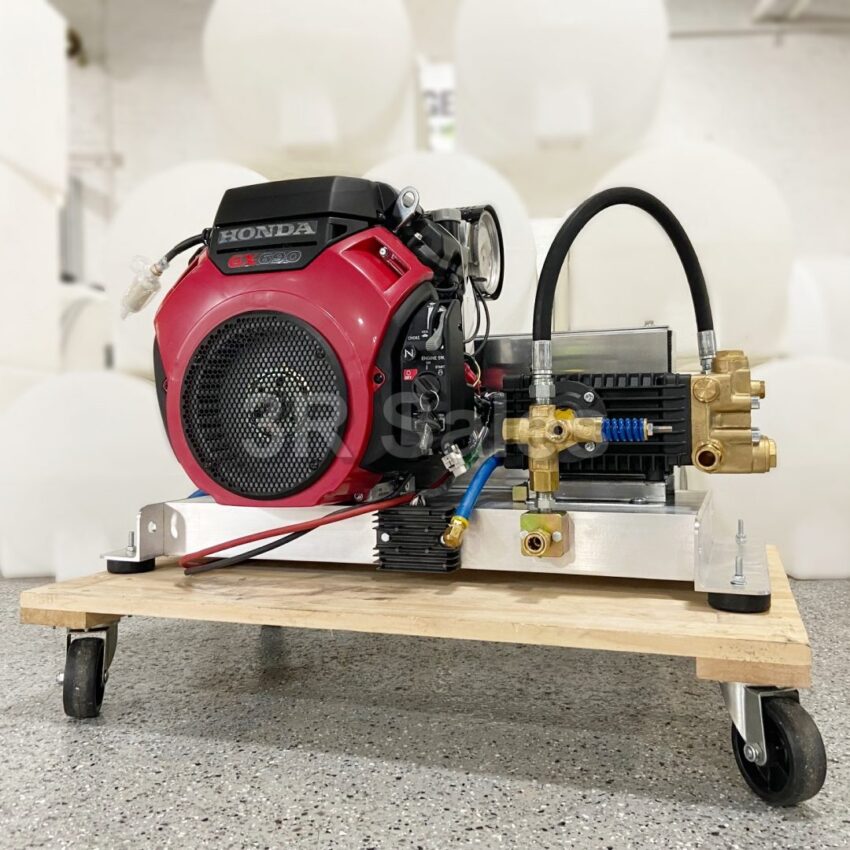

The pump systems in commercial 8 GPM pressure washers are engineered for continuous duty cycles, featuring robust triplex plunger designs that can withstand hours of operation without degradation. These pumps typically incorporate ceramic or stainless steel plungers, premium seals, and oversized bearings to ensure longevity under demanding conditions. The substantial water flow requires equally robust internal components, including larger water passages, reinforced manifolds, and heavy-duty unloader valves capable of handling the significant flow volumes.

Engine requirements for 8 GPM units are correspondingly substantial, with most models requiring 24 to 35 horsepower to drive the high-capacity pumps effectively. Gas-powered units dominate this category due to their power-to-weight ratio and operational flexibility, though electric models are available for stationary applications with adequate power infrastructure. The substantial power requirements mean these machines are typically mounted on wheeled frames or trailers for mobility, making them ideal for contractor use and large facility maintenance.

Commercial Applications for 8 GPM Pressure Washers

Industrial 8 GPM pressure washers excel in applications where both cleaning power and efficiency are paramount. Fleet washing operations represent one of the most common commercial uses, where the high flow rate enables rapid cleaning of large vehicles, trucks, and equipment. The substantial water volume effectively rinses away road salt, mud, and accumulated grime that would require significantly more time with lower-flow units. Fleet managers report cleaning time reductions of 40-60% when upgrading from 4-5 GPM units to 8 GPM systems.

Construction and heavy equipment cleaning present another ideal application for high-flow pressure washers. Construction equipment operates in extremely harsh conditions, accumulating concrete residue, mud, grease, and other stubborn contaminants that demand aggressive cleaning action. The 8 GPM flow rate provides the flushing power necessary to remove embedded dirt from intricate equipment surfaces, undercarriages, and hydraulic components without requiring excessive dwelling time or multiple passes.

Primary Commercial Applications:

- Fleet Vehicle Washing: Trucks, buses, delivery vehicles

- Construction Equipment Cleaning: Excavators, bulldozers, concrete equipment

- Building Exterior Washing: Large commercial structures, warehouses

- Parking Lot and Driveway Cleaning: Shopping centers, industrial facilities

- Agricultural Equipment Maintenance: Tractors, harvesters, irrigation systems

- Marine Applications: Boat hulls, dock cleaning, marine equipment

Agricultural applications particularly benefit from the cleaning power of 8 gallon per minute pressure washers. Farm equipment operates in conditions that create unique cleaning challenges, including soil accumulation, pesticide residues, and organic matter that can harbor pathogens. The high flow rate enables thorough cleaning of complex agricultural machinery, including combines, tractors, and specialized harvesting equipment, ensuring optimal performance and preventing contamination between different crops or fields.

Municipal and government applications represent a growing market for 8 GPM units, particularly for maintenance of public infrastructure. Street cleaning, sidewalk restoration, graffiti removal, and facility maintenance all benefit from the efficiency gains these machines provide. The ability to clean large areas quickly translates to reduced labor costs and minimized disruption to public services, making them attractive investments for budget-conscious municipalities.

Performance Advantages of High-Flow Pressure Washers

The performance benefits of 8 GPM pressure washer systems extend beyond simple cleaning speed improvements. The high flow rate creates a more effective cleaning dynamic that actually improves cleaning quality while reducing overall resource consumption. When compared to multiple smaller units or extended cleaning times with lower-flow equipment, 8 GPM systems often demonstrate superior results with less total water usage per square foot cleaned.

Suggested read: Powerhorse Pressure Washer: Performance-Driven Cleaning Solutions for Every Task

Heat retention represents another significant advantage of high-flow systems, particularly relevant for hot water applications. The larger water volume maintains temperature more effectively during extended cleaning sessions, ensuring consistent cleaning performance throughout the operation. This thermal stability is crucial for applications involving grease removal, sanitization requirements, or cleaning in cold weather conditions where heat loss can significantly impact effectiveness.

Performance Benefits:

| Advantage | 8 GPM System | Lower Flow Alternative |

|---|---|---|

| Cleaning Speed | 40-60% faster | Baseline |

| Water Efficiency | 15-25% better per sq ft | Higher total usage |

| Heat Retention | Excellent | Moderate to poor |

| Surface Coverage | Superior | Limited |

| Rinse Effectiveness | Outstanding | Adequate |

The superior rinsing capability of high-capacity pressure washers cannot be understated in professional applications. Many cleaning failures result not from inadequate initial soil removal, but from insufficient rinsing that leaves residual detergents, loosened contaminants, or cleaning compounds on surfaces. The 8 GPM flow provides the volume necessary to completely flush away all cleaning residues, preventing streaking, spotting, and potential surface damage from chemical residues.

Surface preparation applications particularly benefit from the flow characteristics of 8 GPM systems. When preparing surfaces for painting, coating, or other treatments, complete removal of all contaminants is essential for proper adhesion. The high flow rate ensures thorough removal of chalk, oxidation, loose paint, and other surface contaminants that might compromise subsequent treatments. This thoroughness often eliminates the need for secondary cleaning steps, streamlining project timelines and reducing overall costs.

Selecting the Right 8 GPM Pressure Washer

Choosing an appropriate 8 GPM pressure washer requires careful consideration of specific application requirements, operational constraints, and long-term reliability factors. The substantial investment these machines represent demands thorough evaluation to ensure optimal performance and return on investment. Power source selection represents the first critical decision, with gas and electric options each offering distinct advantages depending on operational requirements.

Gas-powered 8 GPM units provide maximum flexibility and power, making them ideal for mobile applications, remote locations, and situations where electrical infrastructure is inadequate. The power-to-weight ratio of gas engines enables more compact designs while delivering the substantial horsepower required for consistent 8 GPM operation. However, gas units require more maintenance, generate emissions, and have higher operational noise levels that may limit their use in certain environments.

Electric 8 gallon per minute pressure washers offer several operational advantages, including lower noise levels, zero emissions, reduced maintenance requirements, and more consistent power delivery. However, they require substantial electrical infrastructure, typically 240V service with 50-60 amp capacity, limiting their use to fixed installations or locations with adequate power availability. The higher initial electrical installation costs must be weighed against long-term operational savings and environmental benefits.

Selection Criteria:

Suggested read: Electric Hot Water Pressure Washer: Professional Cleaning Power That Transforms Your Business Operations

- Intended Applications: Mobile vs. stationary use requirements

- Power Infrastructure: Available electrical capacity or gas preferences

- Duty Cycle: Continuous operation vs. intermittent use patterns

- Environmental Constraints: Noise, emission, and space limitations

- Budget Considerations: Initial cost vs. operational expenses

- Service Support: Local dealer network and parts availability

Hot water capability represents another crucial consideration for many commercial applications. Hot water 8 GPM pressure washers excel in grease removal, sanitization applications, and cold weather operations, but require additional investment in heating systems and fuel infrastructure. The decision between hot and cold water units should be based on specific cleaning requirements, with many operations benefiting from the versatility of hot water capability even if not used continuously.

Pump construction and warranty coverage deserve careful evaluation given the substantial flow rates involved. Premium triplex pumps with ceramic plungers and robust manifold construction typically justify their higher cost through extended service life and reduced maintenance requirements. Warranty terms often reflect manufacturer confidence in construction quality, with better units typically offering longer coverage periods and more comprehensive protection.

Maintenance and Operational Considerations

Proper maintenance of commercial 8 GPM pressure washers is essential for reliable operation and equipment longevity. The high flow rates and substantial pressures involved create more demanding operating conditions that require systematic maintenance protocols. Pump maintenance represents the most critical aspect, with regular oil changes, seal inspections, and pressure relief valve testing forming the foundation of preventive care.

Water quality significantly impacts the longevity and performance of high-flow pressure washing systems. Hard water, with high mineral content, can create scale buildup in pump chambers, heat exchangers, and internal passages. The substantial flow rates in 8 GPM systems accelerate these effects, making water treatment or filtration particularly important in areas with poor water quality. Regular descaling procedures should be implemented based on local water conditions and usage patterns.

Essential Maintenance Tasks:

- Daily: Check engine oil, inspect hoses and connections, verify water supply

- Weekly: Clean inlet screens, check pump oil level, inspect trigger gun operation

- Monthly: Change pump oil, inspect high-pressure hoses, test pressure relief valve

- Seasonal: Winterize system, inspect engine components, replace filters

- Annual: Comprehensive pump inspection, engine tune-up, hose replacement assessment

Winter storage and freeze protection require special attention for 8 gallon per minute pressure washers due to their substantial internal water volumes. Standard antifreeze procedures may be insufficient for the larger pump chambers and extended hose runs typical of these systems. Compressed air purging followed by appropriate antifreeze circulation ensures complete protection against freeze damage that could destroy expensive pump components.

Operator training becomes particularly important with high-capacity pressure washing equipment. The substantial flow rates and cleaning power can cause surface damage, injury, or equipment damage if improperly used. Training should cover proper nozzle selection, surface preparation techniques, chemical handling procedures, and safety protocols specific to high-flow operations. Many manufacturers offer comprehensive training programs that can significantly improve operational efficiency and safety.

Cost Analysis and Return on Investment

The investment required for industrial 8 GPM pressure washers typically ranges from $3,000 to $8,000 for quality commercial units, with premium hot water systems commanding higher prices. This initial investment must be evaluated against operational savings, productivity improvements, and revenue generation potential to determine overall value proposition. For commercial cleaning operations, the efficiency gains often justify the higher initial cost through reduced labor requirements and increased job capacity.

Suggested read: Best Windscreen Washer Fluid: Top Picks for Crystal Clear Visibility

Labor cost reduction represents the most immediate benefit of upgrading to 8 GPM capacity. Professional cleaning operations report time savings of 40-60% for comparable cleaning tasks, directly translating to reduced labor costs or increased job capacity. For operations billing by the hour, this efficiency gain enables higher profit margins. For fixed-price contracts, the time savings allow more jobs to be completed within the same timeframe, increasing overall revenue potential.

Cost Comparison Analysis:

| Factor | 8 GPM System | Multiple Smaller Units |

|---|---|---|

| Initial Investment | $4,000-$8,000 | $6,000-$12,000 total |

| Labor Efficiency | Single operator | Multiple operators needed |

| Fuel Consumption | Optimized | Higher total consumption |

| Maintenance Costs | Centralized | Multiple systems |

| Storage Requirements | Compact | Extensive |

Water consumption analysis often reveals surprising efficiency advantages for high-flow pressure washers. While 8 GPM units consume more water per minute of operation, their superior cleaning efficiency often results in lower total water usage per square foot cleaned. The effective rinsing capability reduces the need for multiple cleaning passes, while the powerful cleaning action often eliminates the need for pre-soaking or extended dwell times that consume additional water.

Equipment reliability and service life significantly impact total cost of ownership. Quality 8 GPM units designed for commercial service typically provide 5-10 years of reliable operation with proper maintenance, compared to 2-3 years for lighter-duty alternatives subjected to heavy use. The longer service life amortizes the higher initial investment over an extended period while reducing the disruption and costs associated with frequent equipment replacement.

Integration with Cleaning Systems and Accessories

8 GPM pressure washer systems serve as the foundation for comprehensive cleaning solutions that can be enhanced through strategic accessory selection and system integration. Surface cleaners designed for high-flow applications can dramatically improve productivity for large flat surface cleaning while providing more consistent results than hand-held spray guns. These accessories must be properly matched to the 8 GPM flow rate to achieve optimal performance and avoid operational issues.

Chemical injection systems become particularly effective when paired with high-flow pressure washers. The substantial water volume provides excellent chemical dilution and distribution, ensuring consistent application across large surfaces. Downstream chemical injection systems are typically preferred for 8 GPM applications, as they can handle the higher flow rates more effectively than upstream systems while providing better chemical metering accuracy.

Compatible Accessories:

- Surface Cleaners: 20-30 inch units designed for 8+ GPM flow

- Chemical Injection Systems: Downstream injectors with high-flow capacity

- Hose Reels: Heavy-duty reels rated for high-pressure, high-flow applications

- Quick-Connect Fittings: High-flow rated connectors for operational efficiency

- Pressure Regulation: Adjustable unloaders for application-specific pressure control

- Water Filtration: Inlet filtration systems for water quality protection

Hose selection becomes critical with 8 gallon per minute pressure washers due to the substantial flow requirements. Standard 3/8-inch hoses create excessive pressure drop and flow restriction, necessitating 1/2-inch or larger hoses for optimal performance. The larger hoses are heavier and more expensive but essential for realizing the full potential of high-flow systems. Hose length should be minimized to reduce pressure drop, with strategically positioned equipment reducing the need for extended hose runs.

Suggested read: Non Toxic Body Wash: The Best Clean Beauty Picks for Safer Skin in 2026

Water supply infrastructure requires careful consideration for 8 GPM operations. Standard residential water supplies may be inadequate for continuous 8 GPM flow, particularly in areas with low water pressure or restrictive plumbing. Water storage tanks, booster pumps, or direct connection to high-capacity water sources may be necessary for optimal performance. The substantial flow requirements make water supply planning essential for successful commercial operations.

Ready to upgrade your cleaning operations with professional-grade equipment? Explore our complete selection of 8 GPM pressure washers designed for commercial and industrial applications. Our expert team can help you select the perfect system for your specific cleaning requirements and operational constraints.

For additional information on pressure washer options, including compact solutions for smaller applications, check out our comprehensive review of blue clean pressure washer models that offer reliable performance for residential and light commercial use.

Sources: Pressure washer performance data compiled from manufacturer specifications and independent testing results. Commercial application insights based on industry surveys and professional user feedback.