Selecting the right pressure washer attachment can dramatically transform your cleaning capabilities and efficiency. Whether you’re tackling stubborn grime on your driveway, cleaning delicate surfaces on your deck, or reaching high gutters on your home’s exterior, the proper attachment makes all the difference between frustrating cleaning sessions and professional-quality results. The right pressure washer attachment not only enhances your machine’s versatility but also protects surfaces from damage while maximizing cleaning power.

Modern pressure washing technology has evolved far beyond simple spray guns, offering specialized attachments designed for specific cleaning challenges. From surface cleaners that eliminate streaking patterns to foam cannons that pre-treat stubborn stains, today’s pressure washer attachment options provide solutions for virtually every outdoor cleaning scenario. Understanding which attachments work best for your specific needs can save time, prevent property damage, and deliver consistently superior results.

Understanding Pressure Washer Attachment Fundamentals

What Makes a Quality Pressure Washer Attachment?

A superior pressure washer attachment combines durability, functionality, and compatibility to deliver consistent performance across various cleaning applications. High-quality accessories don’t just spit out water; they optimize water flow and pressure for maximum cleaning power, ensuring that every drop of water contributes to effective cleaning rather than waste.

The construction quality of pressure washer attachments directly impacts their longevity and effectiveness. Professional-grade attachments typically feature corrosion-resistant materials such as stainless steel, brass, or high-quality polymers that withstand the harsh conditions of pressure washing environments. These materials resist chemical degradation from detergents and maintain structural integrity under high-pressure conditions, ensuring reliable performance over years of use.

Key Quality Indicators:

- Material Composition: Stainless steel and brass components resist corrosion

- Pressure Rating: Must match or exceed your washer’s maximum PSI

- Flow Rate Compatibility: Should align with your machine’s GPM output

- Connection Type: Proper fitting ensures leak-free operation

- Build Quality: Reinforced joints prevent failure under stress

Compatibility and Connection Types

Understanding pressure washer attachment compatibility prevents costly mistakes and ensures optimal performance. Gas pressure washers are more universal, making it easier to match various accessories and couplings to them. However, electric pressure washers will be mostly brand specific, meaning only specific accessories or parts from the same manufacturer will be compatible.

The most common connection standards include M22 threaded connections, quick-connect couplers, and bayonet-style fittings. Each system offers distinct advantages, with quick-connect systems providing rapid attachment changes during cleaning sessions, while threaded connections deliver maximum security for high-pressure applications. Professional users often prefer quick-connect systems for their versatility and time-saving capabilities.

Standard Connection Types:

- M22 Threaded: Universal standard for most gas pressure washers

- Quick Connect (1/4″): Rapid attachment system for efficiency

- Bayonet Fitting: Twist-lock mechanism for secure connection

- 3/8″ Threaded: Common on commercial-grade equipment

- Proprietary Systems: Brand-specific connections requiring matching components

Suggested read: The Ultimate Rinseless Wash Solution: How to Clean Your Car Anywhere Without Water

Essential Nozzle Types and Applications

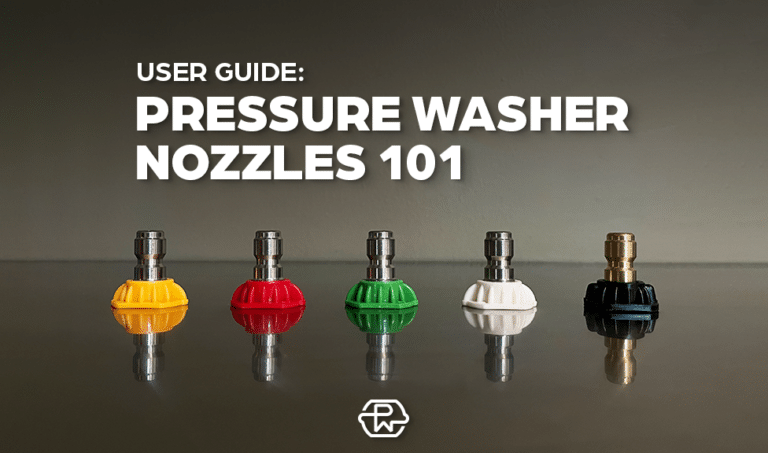

Color-Coded Spray Patterns

Pressure washer nozzles are universally colour coded so operators can easily choose the best one for the job, creating a standardized system that prevents confusion and surface damage. Each color represents a specific spray angle and pressure concentration, allowing users to select the appropriate pressure washer attachment for their specific cleaning requirements.

Standard Color Coding System:

| Color | Spray Angle | Pressure Level | Best Applications |

|---|---|---|---|

| Red | 0° | Maximum | Paint removal, tough stains |

| Yellow | 15° | High | Concrete, metal surfaces |

| Green | 25° | Medium | General purpose cleaning |

| White | 40° | Low | Delicate surfaces, vehicles |

| Black | 65° | Soap | Detergent application only |

The red nozzle delivers the most concentrated pressure in a pencil-thin stream, making it ideal for removing stubborn paint, rust, or deeply embedded stains. However, this pressure washer attachment requires extreme caution as it can easily damage surfaces, etch concrete, or cause injury. Professional contractors often reserve red nozzles for specific applications where maximum cutting power is essential.

Variable Spray Nozzles

Variable spray nozzles represent the ultimate in pressure washer attachment versatility, allowing users to adjust spray patterns from 0° to 40° with a simple twist. These attachments eliminate the need to carry multiple nozzles and enable real-time pressure adjustments without interrupting cleaning workflows. Advanced variable nozzles incorporate pressure regulation features that maintain consistent cleaning power across different spray angles.

The convenience of variable spray pressure washer attachments makes them particularly valuable for residential users who tackle diverse cleaning projects. From washing cars with wide, gentle spray patterns to removing graffiti with concentrated streams, these attachments adapt to changing requirements seamlessly. Professional models often include pressure gauges and flow indicators that help users optimize settings for maximum efficiency.

Variable Nozzle Advantages:

- Continuous Adjustment: Seamless transition between spray patterns

- Space Saving: Replaces multiple fixed nozzles

- Time Efficient: No attachment changes during cleaning

- Pressure Control: Maintains optimal cleaning power

- Versatile Applications: Handles diverse cleaning challenges

Suggested read: Reducing Washer: Everything You Need to Know About This Essential Plumbing Component

Specialized Surface Cleaner Attachments

Rotary Surface Cleaners

Rotary surface cleaners revolutionize flat surface cleaning by eliminating the zebra-striping patterns common with standard pressure washer attachments. These specialized tools feature rotating nozzles enclosed within a housing that maintains consistent distance from the surface, delivering uniform cleaning results across driveways, sidewalks, and decks. Surface cleaners clean quickly & easily, making them indispensable for large area cleaning projects.

The rotating action of these pressure washer attachments creates overlapping spray patterns that prevent streaking while increasing cleaning speed by up to 300% compared to traditional wand cleaning methods. Professional-grade surface cleaners incorporate adjustable pressure settings and interchangeable nozzles, allowing customization for different surface materials and contamination levels. The enclosed design also reduces overspray, protecting nearby plants and surfaces from accidental damage.

Surface Cleaner Benefits:

- Uniform Results: Eliminates streaking and missed spots

- Increased Speed: Covers large areas rapidly

- Reduced Fatigue: Less physical strain than wand cleaning

- Overspray Protection: Contained cleaning action

- Professional Finish: Consistent, commercial-quality results

Concrete and Driveway Cleaners

Specialized concrete cleaning attachments address the unique challenges of heavily soiled surfaces through enhanced pressure distribution and debris management systems. These pressure washer attachments often incorporate vacuum recovery systems that simultaneously extract loosened debris and contaminated water, preventing recontamination and environmental concerns. Advanced models feature adjustable height settings and interchangeable brush systems for different surface textures.

The design of concrete-specific pressure washer attachments accounts for the porous nature of concrete surfaces, which can trap oil, grease, and other contaminants deep within the material. Multi-stage cleaning systems pre-treat stains with detergent application, follow with high-pressure cleaning, and conclude with thorough rinsing to achieve professional-quality results that restore concrete surfaces to their original appearance.

Suggested read: Pan Washer: Everything You Need to Know About This Essential Plumbing Component

Extension and Telescoping Wands

Reach Enhancement Solutions

A telescoping wand is perfect for extending the reach of your pressure washer. It allows you clean in high, hard-to-reach places like gutters, windows, tall equipment, transforming your pressure washer into a versatile tool capable of handling multi-story cleaning challenges safely from ground level.

Professional pressure washer wands incorporate lightweight materials such as carbon fiber or aluminum alloy that maintain strength while reducing user fatigue during extended cleaning sessions. Advanced telescoping mechanisms feature secure locking systems that prevent accidental collapse under pressure, ensuring operator safety and consistent cleaning performance. These pressure washer attachment solutions often include rotating heads that enable precise angle adjustments for optimal cleaning effectiveness.

Extension Wand Features:

- Adjustable Length: Extends from 4 to 24 feet typically

- Lightweight Construction: Reduces operator fatigue

- Secure Locking: Prevents accidental collapse

- Rotating Heads: Enable precise angle control

- Quick-Connect Compatible: Works with standard nozzle systems

Safety Considerations for Extended Reach

Extended reach pressure washer attachments require additional safety precautions due to increased leverage forces and reduced control precision. The longer moment arm created by extension wands amplifies kickback forces, potentially causing loss of control or operator injury. Professional-grade extensions incorporate ergonomic grips, vibration dampening, and safety lanyards to maintain operator control under all conditions.

Proper training in extended reach pressure washer attachment use includes understanding wind effects on high-pressure spray patterns, maintaining stable footing on ladders or elevated platforms, and recognizing electrical hazards when cleaning near power lines. Many professional contractors implement specific protocols for extended reach cleaning that include ground spotters and communication systems to ensure operator safety.

Suggested read: ONR Wash: The Waterless Car Cleaning Revolution That's Changing Vehicle Care Forever

Foam Cannon and Chemical Application Attachments

Pre-Treatment Systems

Foam cannon pressure washer attachments revolutionize the cleaning process by applying thick, clinging foam that penetrates and loosens stubborn contaminants before high-pressure washing begins. These specialized systems create rich, dense foam from concentrated detergents, extending contact time and reducing the mechanical action required for effective cleaning. Professional-grade foam cannons feature adjustable dilution ratios and spray patterns for optimal coverage.

The chemistry behind effective foam cannon pressure washer attachments involves surfactant technology that reduces water surface tension, allowing cleaning solutions to penetrate deeply into porous surfaces and under stubborn stains. Advanced systems incorporate multiple chemical injection points, enabling the simultaneous application of different cleaning agents for complex contamination scenarios. This pre-treatment approach often reduces overall cleaning time while improving results quality.

Foam Cannon Advantages:

- Enhanced Cleaning Power: Pre-treatment loosens stubborn stains

- Chemical Efficiency: Optimizes detergent concentration and contact time

- Surface Protection: Reduces high-pressure exposure requirements

- Visual Coverage: Foam indicates treated areas

- Professional Results: Achieves commercial-quality cleaning

Chemical Injector Systems

Chemical injector pressure washer attachments provide precise control over detergent application rates and mixture concentrations, ensuring optimal cleaning performance while minimizing chemical waste. These systems draw cleaning solutions directly from concentrate containers, automatically diluting them to predetermined ratios based on water flow rates. Advanced injectors feature multiple intake ports for different cleaning chemicals.

Professional chemical injection pressure washer attachments incorporate flow meters, pressure regulators, and mixing chambers that ensure consistent chemical delivery regardless of operating conditions. These systems often include quick-disconnect fittings for rapid changeover between different cleaning solutions, enabling efficient handling of varied cleaning challenges within single projects. Safety features prevent accidental chemical mixing and provide emergency shutdown capabilities.

Suggested read: Commercial Glass Washers: Why Your Business Needs Professional Glassware Cleaning Equipment

Water Broom and Wide-Area Cleaning Attachments

Large Surface Coverage Solutions

Water brooms are an accessory that you can add to any pressure washer. The water broom allows you to clean a large area with a spray bar and casters with nozzles, providing efficient coverage for expansive surfaces such as parking lots, warehouses floors, and large driveways.

Water broom pressure washer attachments typically feature multiple nozzles arranged across a wide spray bar, creating overlapping cleaning patterns that eliminate streaking while covering substantial areas in single passes. Professional models incorporate adjustable nozzle angles, interchangeable tips, and height adjustment mechanisms that accommodate different surface types and cleaning requirements. The wheeled design reduces operator fatigue while maintaining consistent surface distance for uniform results.

Water Broom Specifications:

- Coverage Width: Typically 12 to 36 inches

- Nozzle Configuration: 3 to 7 spray points

- Pressure Requirements: 1000-4000 PSI

- Flow Rate: 3-4 GPM optimal

- Mobility Features: Smooth-rolling casters

Commercial Applications

Commercial-grade water broom pressure washer attachments address the demanding requirements of industrial cleaning applications through heavy-duty construction and enhanced durability features. These systems incorporate stainless steel spray bars, reinforced wheel assemblies, and corrosion-resistant components that withstand harsh industrial environments and aggressive cleaning chemicals.

The efficiency gains provided by commercial water broom attachments translate directly into labor cost savings and improved productivity for professional cleaning operations. Large-scale applications such as airport runways, manufacturing facilities, and municipal maintenance projects benefit significantly from the wide coverage and consistent results these pressure washer attachments deliver.

Suggested read: Embassy Wash: The Ultimate Solution for Professional Glass Cleaning and Detailing

Maintenance and Care for Pressure Washer Attachments

Cleaning and Storage Protocols

Proper maintenance extends pressure washer attachment lifespan and ensures consistent performance throughout their service life. Regular cleaning removes chemical residues, salt deposits, and debris that can cause internal corrosion or blockages. Professional maintenance protocols include thorough flushing with clean water after each use, followed by complete drying to prevent moisture-related deterioration.

Storage conditions significantly impact pressure washer attachment longevity. Controlled temperature environments prevent material degradation from extreme temperature cycling, while proper humidity levels reduce corrosion risks. Professional-grade storage systems include protective cases, organized hanging systems, and inventory tracking methods that prevent damage and ensure availability when needed.

Maintenance Best Practices:

- Post-Use Flushing: Remove chemical residues thoroughly

- Complete Drying: Prevent internal moisture retention

- Regular Inspection: Check for wear, damage, or blockages

- Proper Storage: Controlled environment with protective cases

- Inventory Management: Track condition and replacement needs

Troubleshooting Common Issues

Common pressure washer attachment problems include reduced pressure output, irregular spray patterns, and connection leaks. Pressure reduction often results from nozzle blockages caused by debris or mineral deposits, requiring careful cleaning with appropriate tools to restore proper flow. Irregular spray patterns typically indicate worn nozzle orifices or damaged internal components requiring replacement.

Connection leaks represent safety hazards and efficiency losses that demand immediate attention. O-ring replacement, thread cleaning, and proper torque specifications resolve most connection issues. Advanced troubleshooting may require pressure testing and flow measurement to identify internal component failures or compatibility problems with specific pressure washer models.

Suggested read: Dr Wash: Transform Your Vehicle Care with Professional Auto Detailing Services

Choosing the Right Pressure Washer Attachment for Your Needs

Residential vs Commercial Requirements

Residential pressure washer attachment selection focuses on versatility, ease of use, and storage convenience for typical homeowner cleaning projects. Choose according to the type of pressure washer tasks you undertake and the pressure washer and attachments you already have. Homeowners benefit most from multi-purpose attachments that handle diverse cleaning challenges without requiring extensive attachment collections.

Commercial pressure washer attachment requirements emphasize durability, efficiency, and specialized functionality for professional cleaning operations. Commercial users typically require multiple specialized attachments optimized for specific applications, along with rapid changeover capabilities and robust construction that withstands intensive daily use. Professional systems often incorporate productivity features such as extended warranties and field-serviceable components.

Selection Criteria Comparison:

| Factor | Residential | Commercial |

|---|---|---|

| Durability | Moderate use | Heavy-duty construction |

| Versatility | Multi-purpose preferred | Task-specific optimization |

| Storage | Compact solutions | Organized systems |

| Budget | Cost-effective | ROI-focused investment |

| Maintenance | Simple procedures | Professional servicing |

Performance Matching Guidelines

Optimal pressure washer attachment performance requires careful matching between attachment specifications and pressure washer capabilities. Flow rate compatibility ensures adequate water supply for attachment operation, while pressure ratings prevent damage or unsafe conditions. Ensure compatibility with your pressure washer model for proper function, ease of use and safe operation.

Performance matching extends beyond basic compatibility to include optimization factors such as cleaning efficiency, chemical consumption, and operator comfort. Professional applications often require detailed performance analysis to maximize productivity and minimize operating costs. Advanced matching considerations include environmental factors, surface materials, and contamination types that influence attachment selection.

Suggested read: The Complete Camper Wash Blueprint: Transform Your RV From Filthy to Sparkling in 2025

Cost Analysis and Return on Investment

Budget Considerations

Pressure washer attachment investments range from basic utility options under $20 to professional-grade systems exceeding $500, with performance and durability scaling accordingly. Budget-conscious consumers can achieve significant cleaning improvements with basic nozzle sets and simple extension wands, while commercial operators typically require higher-investment specialized attachments for optimal productivity.

The cost-effectiveness of pressure washer attachments extends beyond initial purchase price to include operational efficiency, maintenance requirements, and replacement intervals. Professional-grade attachments often provide superior total cost of ownership through extended service life, reduced maintenance needs, and improved cleaning efficiency that translates into labor savings.

Cost Categories:

- Basic Nozzle Sets: $15-40 for homeowner applications

- Extension Wands: $30-150 depending on length and materials

- Surface Cleaners: $80-400 for various sizes and features

- Foam Cannons: $25-200 based on construction quality

- Professional Systems: $200-800+ for commercial applications

Productivity Benefits

Quality pressure washer attachments deliver measurable productivity improvements through increased cleaning speed, improved results quality, and reduced physical effort requirements. Surface cleaners can increase flat surface cleaning speed by 200-300% compared to traditional wand methods, while foam cannons reduce scrubbing requirements and chemical consumption through enhanced pre-treatment effectiveness.

Professional cleaning operations document significant return on investment from specialized pressure washer attachments through reduced labor costs, improved customer satisfaction, and expanded service capabilities. Many commercial operators report attachment payback periods of less than six months for frequently used specialized tools, making quality attachments essential business investments rather than optional accessories.

Suggested read: Best Boat Wash Solutions: How to Keep Your Vessel Spotless in 2025

Safety Guidelines and Best Practices

Operator Protection Requirements

Pressure washer attachment operation requires comprehensive personal protective equipment including safety glasses, protective footwear, and appropriate clothing to prevent injury from high-pressure water streams and chemical exposure. Professional operators often utilize face shields, protective suits, and hearing protection during intensive cleaning operations or when working with specialized chemical systems.

Training requirements for pressure washer attachment use include understanding pressure ratings, proper connection procedures, and emergency shutdown protocols. Advanced safety training covers specific hazards associated with specialized attachments such as chemical injection systems, extended reach wands, and high-pressure surface cleaners. Regular safety refresher training ensures continued compliance with evolving safety standards.

Essential Safety Equipment:

- Eye Protection: Safety glasses or face shields

- Footwear: Non-slip, chemical-resistant boots

- Clothing: Long sleeves and pants for splash protection

- Gloves: Chemical-resistant when handling detergents

- Hearing Protection: For prolonged high-pressure operation

Environmental Considerations

Responsible pressure washer attachment use includes consideration of environmental impacts from chemical runoff, water consumption, and waste management. Modern cleaning protocols emphasize biodegradable detergents, water recovery systems, and contamination containment methods that minimize environmental impact while maintaining cleaning effectiveness.

Professional cleaning operations increasingly implement environmental management systems that track water usage, chemical consumption, and waste generation associated with different pressure washer attachments. These systems enable optimization of cleaning processes for both efficiency and environmental responsibility, often revealing opportunities for significant resource conservation without compromising cleaning quality.

Suggested read: Wash Depot: Your Ultimate Destination for Professional Vehicle Cleaning Solutions

Frequently Asked Questions About Pressure Washer Attachments

What is the most versatile pressure washer attachment for homeowners?

Variable spray nozzles represent the most versatile pressure washer attachment for residential use, offering adjustable spray patterns from 0° to 40° in a single tool. This eliminates the need for multiple fixed nozzles while providing appropriate pressure levels for diverse cleaning tasks from delicate surfaces to stubborn stains.

How do I know if a pressure washer attachment will fit my machine?

Compatibility depends on your pressure washer’s connection type, pressure rating, and flow rate. Check your owner’s manual for specifications, then match attachments with compatible connection types (M22, quick-connect, etc.) and pressure ratings that don’t exceed your machine’s capabilities.

Can pressure washer attachments increase cleaning power beyond my machine’s rating?

No, pressure washer attachments cannot increase your machine’s fundamental pressure or flow rate capabilities. However, they can optimize the delivery of available power through focused spray patterns, pre-treatment systems, and efficient coverage methods that improve cleaning effectiveness.

What’s the difference between residential and commercial pressure washer attachments?

Commercial attachments feature heavier construction, higher pressure ratings, and specialized functionality for professional applications. They typically cost more but offer superior durability and performance for intensive daily use, while residential attachments prioritize versatility and cost-effectiveness for occasional use.

How often should I replace pressure washer attachments?

Replacement frequency depends on usage intensity and attachment quality. Residential users may use basic attachments for several years with proper maintenance, while commercial operators might replace heavily used attachments annually. Regular inspection for wear, damage, or performance degradation guides replacement timing.

Are expensive pressure washer attachments worth the investment?

Quality attachments provide superior performance, durability, and safety compared to basic alternatives. For frequent users or commercial applications, premium attachments often pay for themselves through improved efficiency, reduced replacement costs, and better cleaning results. Occasional users may find mid-range options provide optimal value.

Ready to transform your cleaning capabilities? Explore our comprehensive selection of professional-grade pressure washer attachments designed to maximize your cleaning efficiency and deliver professional-quality results. From specialized surface cleaners to versatile extension wands, find the perfect pressure washer attachment solution for your specific cleaning challenges today.

Sources:

- Pressure Washer Surface Cleaners – Bob Vila – Comprehensive testing of surface cleaner attachments

- Essential Pressure Washer Accessories – TheBlueHose – Professional accessory recommendations

- Pressure Washer Attachments Guide – House Grail – Detailed attachment functionality analysis

- Compatible Pressure Washer Attachments – Pressure Washers Direct – Compatibility and connection standards

- Top Pressure Washer Accessories – Alkota – Commercial-grade attachment specifications