Understanding Washer Lock Washer Fundamentals

A washer lock washer is a critical component in mechanical assemblies that prevents fasteners from loosening due to vibration, thermal expansion, or dynamic loads. Unlike standard flat washers that simply distribute load, lock washers create friction or mechanical interference to maintain bolt tension over time. These specialized fastening components have revolutionized industries ranging from automotive manufacturing to aerospace engineering, where fastener failure can lead to catastrophic consequences. The engineering principle behind lock washers dates back to the early industrial revolution, when manufacturers discovered that standard bolted connections would gradually loosen under operational stress, leading to equipment failure and safety hazards.

The primary function of a washer lock washer extends beyond simple load distribution. These devices create a spring action or mechanical bite that actively resists rotational movement of the fastener. When properly installed, a lock washer maintains constant pressure on the joint interface, compensating for material compression, thermal cycling, and vibrational forces that would otherwise cause traditional fasteners to back out. Modern engineering studies have shown that assemblies using appropriate lock washers can maintain up to 85% of their initial preload after thousands of vibration cycles, compared to just 30-40% for assemblies using only flat washers.

Suggested read: Reducing Washer: Everything You Need to Know About This Essential Plumbing Component

Types of Washer Lock Washers and Their Applications

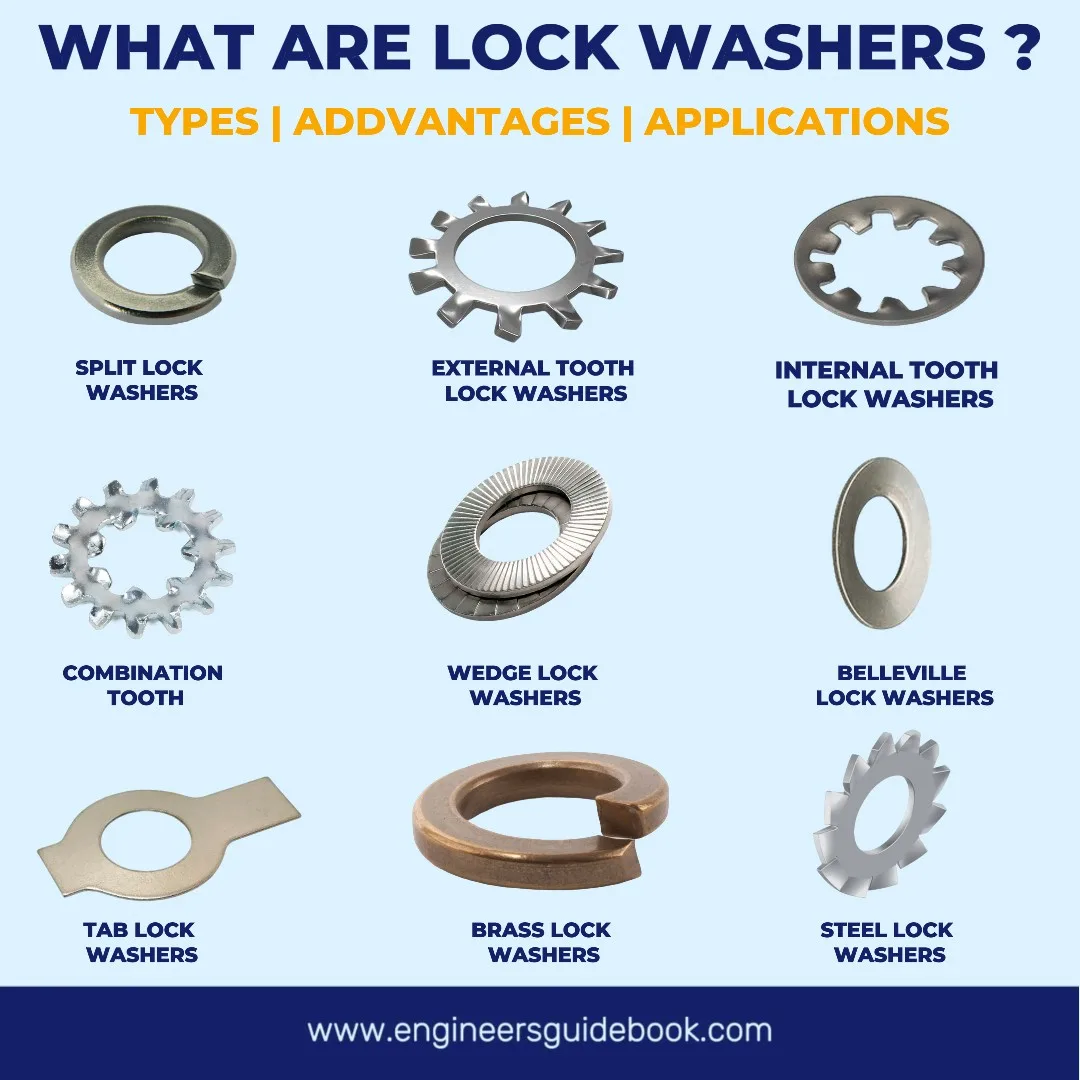

Split Lock Washers (Helical Spring Washers)

Split lock washers represent the most common type of lock washer used across industrial applications. These washers feature a single coil spring design with cut ends that dig into both the fastener head and the bearing surface when compressed. The helical spring action creates tension that resists loosening through friction and mechanical bite. Manufacturing specifications for split lock washers are governed by standards such as ASME B18.21.1 and DIN 127, which define dimensional tolerances, material requirements, and performance characteristics. These washers work best in applications with hard bearing surfaces where the sharp edges can effectively bite into the material.

Split lock washers are manufactured in various materials including carbon steel, stainless steel, bronze, and specialized alloys for high-temperature applications. The effectiveness of a split lock washer depends heavily on proper installation—the gap in the washer should be positioned perpendicular to the direction of potential loosening forces. Industries commonly using split lock washers include automotive assembly lines, HVAC equipment manufacturing, electrical panel construction, and general machinery applications where moderate vibration resistance is required. However, recent engineering research has questioned the effectiveness of split lock washers in high-vibration environments, leading many critical applications to specify alternative locking methods.

Tooth Lock Washers (Internal and External)

Tooth lock washers feature multiple teeth or serrations around their circumference that bite into mating surfaces when compressed. Internal tooth lock washers have teeth pointing inward toward the fastener shaft, making them ideal for applications with limited clearance around the bolt head. External tooth lock washers have teeth pointing outward, providing superior grip on softer materials and larger bearing areas. Some specialized designs feature teeth on both internal and external edges, called combination tooth lock washers, which maximize grip and are particularly effective on painted or coated surfaces where the teeth can penetrate through to bare metal.

The mechanical advantage of tooth lock washers comes from their ability to create multiple points of contact and resistance. Each tooth acts as a miniature wedge that digs into the bearing surface, creating dozens of resistance points compared to the two contact points of a split lock washer. This distributed gripping action makes tooth lock washers particularly effective in electrical applications, where they can cut through oxidation, paint, or coating to establish reliable electrical continuity.

Manufacturing industries report that assemblies using tooth lock washers maintain 70-80% of initial torque after extended vibration testing, making them superior to split washers in many applications. The aerospace industry frequently specifies external tooth lock washers for non-critical fasteners due to their reliable performance and ease of inspection.

Wave Washers and Belleville Washers

Wave washers provide spring action through their corrugated design, which compresses axially to maintain tension in the joint. Unlike traditional lock washers that rely on friction and bite, wave washers function as a spring element that continuously applies force to keep the fastener tight. These washers are manufactured with three or four waves around their circumference, creating predictable spring rates that engineers can calculate for specific applications. Wave washers excel in applications requiring compensation for thermal expansion, where materials expand and contract with temperature changes that would otherwise cause loss of fastener preload.

Belleville washers, also known as disc springs or conical spring washers, represent the heavy-duty category of spring-type lock washers. These washers feature a conical shape that flattens under load, storing significant elastic energy that maintains bolt tension. Belleville washers can be stacked in series or parallel configurations to achieve specific spring rates and load capacities, making them highly versatile for custom applications. The automotive industry extensively uses Belleville washers in suspension systems, engine mounts, and clutch assemblies where maintaining precise preload is critical for performance and safety. Engineering calculations for Belleville washers are more complex than other lock washer types, requiring consideration of cone angle, material properties, and load-deflection characteristics to ensure proper function.

Suggested read: Pan Washer: Everything You Need to Know About This Essential Plumbing Component

Material Selection for Washer Lock Washers

Material selection for washer lock washers critically impacts performance, durability, and compatibility with the application environment. Carbon steel lock washers are the most economical choice for general-purpose applications in dry, non-corrosive environments. These washers are typically heat-treated to achieve hardness ratings between HRC 38-45, providing sufficient hardness to bite into most steel bearing surfaces while maintaining spring properties. Carbon steel lock washers are commonly zinc-plated or phosphate-coated to provide basic corrosion resistance, though these coatings offer limited protection in harsh environments. Manufacturing standards require that carbon steel lock washers meet minimum tensile strength requirements to ensure they don’t permanently deform during installation and use.

Stainless steel lock washers dominate applications requiring corrosion resistance, including marine equipment, food processing machinery, chemical processing plants, and outdoor installations. The most common grades are 18-8 stainless (equivalent to 304) and 316 stainless steel, with 316 offering superior corrosion resistance in chloride-rich environments. However, engineers must consider that stainless steel lock washers are softer than carbon steel equivalents, typically achieving hardness ratings of only HRC 25-35. This reduced hardness limits their effectiveness on hard bearing surfaces but makes them suitable for applications where preventing galling is more important than maximum locking force. The marine industry specifically requires 316 stainless steel lock washers for below-waterline applications due to its superior resistance to saltwater corrosion.

Specialized applications may require exotic materials such as titanium, Inconel, monel, or bronze lock washers. Titanium lock washers are specified in aerospace applications where high strength-to-weight ratio is essential, though their cost is approximately 10-15 times higher than stainless steel alternatives. Inconel and other nickel-based alloys are used in high-temperature applications exceeding 800°F (427°C), such as gas turbine assemblies and exhaust systems. Bronze lock washers find applications in electrical systems where electrical conductivity is important, and in marine hardware where galvanic compatibility with bronze fasteners must be maintained. Material certifications and traceability become critical in regulated industries like aerospace and medical device manufacturing, where lock washer failure could have serious safety implications.

Suggested read: ONR Wash: The Waterless Car Cleaning Revolution That's Changing Vehicle Care Forever

Installation Best Practices for Washer Lock Washers

Proper installation of washer lock washers requires understanding the correct sequence, torque specifications, and inspection criteria to ensure effective fastener locking. The standard installation sequence places the lock washer directly under the rotating component—typically under the nut in a bolt-nut assembly or under the bolt head when threading into a tapped hole. This positioning ensures the lock washer’s gripping action resists the specific rotation direction of loosening. A common installation mistake involves placing flat washers between the lock washer and the rotating element, which defeats the lock washer’s gripping mechanism by preventing it from biting into the proper surface. Engineering specifications should clearly identify washer sequencing to prevent assembly errors that compromise joint integrity.

Torque application significantly affects lock washer performance. Under-torquing fails to compress the lock washer sufficiently, preventing the teeth or edges from biting into bearing surfaces. Studies conducted by fastener manufacturers indicate that lock washers require at least 75% of recommended torque to function properly, with optimal performance occurring at 90-100% of specification. Over-torquing can permanently flatten split lock washers or strip the teeth from tooth lock washers, eliminating their locking function entirely.

Torque specifications must account for the additional friction created by lock washers—assemblies with lock washers typically require 10-20% more torque than identical assemblies with flat washers to achieve the same bolt preload. Modern assembly operations use calibrated torque wrenches or automated torque tools with documented verification to ensure consistent installation across production.

Surface preparation plays a crucial role in lock washer effectiveness. Bearing surfaces should be clean, dry, and free from paint, rust, or excessive coating thickness that might prevent the lock washer from properly engaging. Some industries require surface roughness specifications—typically 125 microinches Ra or rougher—to provide adequate grip for lock washer teeth. However, extremely rough or irregular surfaces can prevent uniform load distribution and create stress concentrations that may lead to fastener failure. The military and aerospace sectors often specify surface preparation procedures and inspection criteria to ensure lock washers will perform as intended in critical applications. Quality control procedures should include visual inspection of installed lock washers to verify proper compression and engagement with bearing surfaces.

Suggested read: Commercial Glass Washers: Why Your Business Needs Professional Glassware Cleaning Equipment

Comparing Washer Lock Washer Performance

| Lock Washer Type | Vibration Resistance | Reusability | Cost Factor | Best Applications |

|---|---|---|---|---|

| Split Lock Washer | Moderate | Poor | 1.0x | General machinery, moderate vibration |

| Internal Tooth | Good | Fair | 1.3x | Electrical connections, limited clearance |

| External Tooth | Good | Fair | 1.2x | Large bearing areas, painted surfaces |

| Wave Washer | Excellent | Good | 2.5x | Thermal cycling, precision preload |

| Belleville Washer | Excellent | Good | 3.0x | High loads, critical assemblies |

The performance comparison reveals significant differences between washer lock washer types that engineers must consider during design. Split lock washers offer the lowest cost and widest availability but provide only moderate vibration resistance and cannot be reliably reused after disassembly. Research conducted by NASA on fastener reliability found that split lock washers lost effectiveness after just one installation cycle, leading to their prohibition in many aerospace applications. Tooth lock washers demonstrate superior performance in vibration testing and can sometimes be reused if the teeth haven’t been completely flattened during initial installation, though most quality standards recommend replacing them during maintenance.

Wave washers and Belleville washers command premium prices due to their manufacturing complexity and superior performance characteristics. However, these higher costs are justified in applications where fastener failure would result in expensive downtime, safety hazards, or warranty claims. The automotive industry conducted extensive testing comparing various lock washer types in engine and chassis applications, finding that wave washers maintained preload more consistently through thermal cycling than any other type tested. Cost-benefit analysis should consider not just the unit price of the lock washer but the total cost of installation, potential failure consequences, and maintenance requirements over the assembly’s service life.

Suggested read: Embassy Wash: The Ultimate Solution for Professional Glass Cleaning and Detailing

Industry Standards and Specifications for Washer Lock Washers

ASME B18.21.1 provides comprehensive dimensional and performance standards for metric and inch-series lock washers manufactured in North America. This standard defines tolerances for outer diameter, inner diameter, thickness, and the critical gap dimension for split lock washers. Manufacturers must meet these specifications to ensure interchangeability—lock washers from different suppliers should fit the same fastener size and provide comparable performance. The standard also specifies material requirements, heat treatment procedures, and finish options including plain, zinc-plated, and cadmium-plated surfaces. Quality control procedures outlined in ASME B18.21.1 require sample testing from production lots to verify hardness, dimensions, and resistance to cracking when compressed.

DIN 127 and DIN 6797 represent the European standards for split lock washers and tooth lock washers respectively. These standards differ slightly from ASME specifications in dimensional tolerances and preferred sizes, though both systems cover similar functional requirements. International projects must carefully specify which standard applies to avoid compatibility issues during assembly. The ISO (International Organization for Standardization) has worked to harmonize these standards through documents like ISO 7089 and ISO 7090, though regional preferences persist in many industries. Global manufacturers often stock both ASME and DIN-compliant lock washers to serve diverse customer bases.

Military and aerospace specifications impose more stringent requirements on washer lock washers for critical applications. MIL-DTL-70411 specifies lock washers for military applications with requirements for material traceability, lot testing, and performance verification under extreme conditions. The Federal Aviation Administration (FAA) publishes advisory circulars providing guidance on acceptable lock washer types for aircraft maintenance, with many applications requiring specific part numbers from approved manufacturer lists. Medical device manufacturers follow FDA guidelines that require documented validation of fastener locking mechanisms, including lock washer performance testing under simulated use conditions. These regulated industries maintain detailed records of lock washer specifications, installation procedures, and inspection results to demonstrate compliance during audits.

Suggested read: Dr Wash: Transform Your Vehicle Care with Professional Auto Detailing Services

Alternatives to Traditional Washer Lock Washers

While washer lock washers remain popular, engineers should evaluate alternative locking methods that may provide superior performance for specific applications. Thread-locking compounds such as Loctite create chemical bonds between mating threads, offering excellent vibration resistance without the installation complexity of lock washers. These compounds are available in various strength grades from temporary-hold formulations easily disassembled with hand tools to permanent grades requiring heat for removal. Thread-locking compounds excel in applications with smooth bearing surfaces where lock washers cannot effectively bite, and in locations where space constraints prevent washer installation. However, they require surface preparation, curing time, and may not be compatible with certain plastics or coatings.

Mechanical locking methods including nylon-insert lock nuts (Nylock), all-metal lock nuts with deformed threads, and castle nuts with cotter pins provide self-contained locking without separate components. These integrated solutions eliminate the possibility of forgetting or losing lock washers during assembly and reduce part count in the bill of materials. All-metal lock nuts maintain performance in high-temperature environments exceeding 250°F (121°C) where nylon inserts would melt. The disadvantage of lock nuts is limited reusability—most types lose effectiveness after 3-5 installation cycles, whereas quality Belleville washers may be reused 10 or more times. Cost analysis must consider both the higher unit price of lock nuts and the labor savings from eliminating a separate component.

Nord-Lock washers represent an advanced alternative gaining acceptance in critical applications. This system uses pairs of wedge-lock washers with cam surfaces and radial teeth that work together to prevent fastener loosening. Testing by independent laboratories has demonstrated that Nord-Lock washers maintain bolt preload under vibration loads that completely loosen assemblies using traditional split lock washers. While Nord-Lock washers cost 5-10 times more than conventional lock washers, they’re being specified increasingly in wind turbine assemblies, heavy construction equipment, and other applications where vibration-induced loosening has caused expensive failures. The wave car wash industry has even adopted advanced fastening systems in automated equipment where vibration from high-speed operations previously caused maintenance problems.

Suggested read: The Complete Camper Wash Blueprint: Transform Your RV From Filthy to Sparkling in 2025

Real-World Case Studies: Washer Lock Washer Failures and Successes

The automotive industry experienced a significant recall in 2018 when a major manufacturer discovered that split lock washers used in steering column assemblies were failing under normal driving vibrations. Engineering analysis revealed that the stamped steel bearing surface was too hard for the lock washers to effectively bite, allowing fasteners to gradually loosen over thousands of miles. The recall affected over 250,000 vehicles and cost the manufacturer an estimated $45 million in warranty repairs, parts replacement, and labor.

The solution involved switching to external tooth lock washers with hardened teeth capable of penetrating the bearing surface, combined with increased torque specifications. This case illustrates the critical importance of matching lock washer type and hardness to the specific bearing surface material and application loads.

A petrochemical processing plant in Texas eliminated repeated pump coupling failures by replacing standard split lock washers with Belleville washer stacks. The couplings connect large electric motors to centrifugal pumps operating at 3,600 RPM with significant vibration and thermal cycling from -20°F during shutdowns to 180°F during operation. Previously, maintenance crews were retorquing coupling bolts every 2-3 months to prevent catastrophic failure, consuming 40+ labor hours annually per pump. After switching to properly calculated Belleville washer stacks, the plant extended maintenance intervals to 18 months with no fastener loosening observed during inspections. The $800 investment in premium washers eliminated approximately $15,000 in annual maintenance labor while reducing the risk of unplanned shutdowns.

The aerospace sector provides compelling evidence for proper lock washer selection through NASA’s fastener reliability program. After investigating several in-flight failures attributed to fastener loosening, NASA implemented stringent requirements prohibiting split lock washers in critical flight hardware. Testing demonstrated that split lock washers provided minimal locking benefit in aircraft-grade aluminum structures and could actually cause fretting corrosion at joint interfaces. NASA now specifies appropriate alternatives including thread-locking compounds, mechanical lock nuts, or properly calculated Belleville washers depending on load requirements, temperature range, and reusability needs. This systematic approach to fastener locking has contributed to improved reliability across space and aviation programs, with documented cost savings from reduced failures exceeding $50 million over a 10-year period.

Suggested read: Best Boat Wash Solutions: How to Keep Your Vessel Spotless in 2025

Purchasing Considerations for Washer Lock Washers

When sourcing washer lock washers, procurement professionals must balance cost, quality, availability, and supplier reliability. Bulk purchasing from major distributors like Fastenal, Grainger, or McMaster-Carr provides competitive pricing and convenient delivery but may limit material options and certifications. Industrial distributors typically stock the most common sizes in carbon steel and stainless steel, with lead times of 1-3 days for standard items. However, specialty materials, non-standard sizes, or washers requiring material certifications may require direct manufacturer purchase with lead times extending to 4-12 weeks. Organizations should maintain relationships with multiple suppliers to ensure continuity during supply chain disruptions—the COVID-19 pandemic exposed vulnerabilities when single-source suppliers experienced extended shutdowns.

Quality verification becomes critical when purchasing lock washers for critical applications. Counterfeit and substandard fasteners have infiltrated supply chains globally, with some estimates suggesting 2-5% of industrial fasteners in circulation fail to meet stated specifications. Visual inspection can identify obvious defects like improper heat treatment (indicated by color variations), dimensional errors, or surface defects. However, verifying material composition and hardness requires testing equipment many purchasing departments lack. Industries operating under quality management systems like ISO 9001 or AS9100 should require mill test reports or certificates of conformance documenting that washers meet applicable standards. Third-party testing services can verify critical purchases when supplier documentation is questionable.

Cost optimization strategies extend beyond simple unit price comparison. Engineering teams should standardize on the minimum number of lock washer types and sizes that satisfy application requirements, enabling larger purchase quantities with better pricing and simplified inventory management. A typical manufacturing facility might stock 20-30 different lock washer specifications compared to potentially hundreds if each engineer specifies different types. Value analysis teams should periodically review lock washer applications to identify opportunities for substituting lower-cost alternatives without compromising performance. However, engineers must carefully evaluate any cost reduction proposals—switching from a $0.15 wave washer to a $0.03 split lock washer might save money on paper but create expensive warranty claims if the substitution proves inadequate for the application.

Suggested read: Wash Depot: Your Ultimate Destination for Professional Vehicle Cleaning Solutions

Environmental and Safety Considerations

Corrosion protection represents a major environmental consideration for washer lock washers exposed to harsh conditions. Standard zinc plating provides adequate protection in indoor applications but fails rapidly in marine, chemical, or high-humidity environments. Salt spray testing per ASTM B117 reveals that zinc-plated washers begin showing red rust after just 24-72 hours of exposure, while stainless steel and specialized coatings resist corrosion for thousands of hours. Hot-dip galvanizing offers superior corrosion protection compared to electroplating but adds thickness that affects dimensional tolerances. Modern coating technologies including geomet, dacromet, and ceramic coatings provide excellent corrosion resistance while maintaining the thin profiles needed for lock washer function.

Environmental regulations impact lock washer selection and disposal, particularly for washers containing hazardous materials. The European Union’s RoHS (Restriction of Hazardous Substances) directive restricts cadmium, lead, and hexavalent chromium in electronic equipment, affecting lock washers used in consumer electronics. California’s Proposition 65 requires warnings for products containing chemicals known to cause cancer or reproductive harm, including some coatings historically used on fasteners. Organizations must maintain documentation demonstrating compliance with applicable regulations, which may require switching to alternative materials or coatings. Proper disposal of used lock washers containing heavy metals or hazardous coatings requires following local environmental regulations—many jurisdictions classify them as industrial waste requiring segregation and licensed disposal.

Workplace safety considerations include proper handling and installation procedures to prevent injuries. Sharp edges on tooth lock washers can cause cuts during handling, requiring workers to use appropriate gloves. Installation of Belleville washers requires attention to orientation—installing them backwards creates an unstable condition that can cause the washer to suddenly flip with sufficient force to cause injury. Training programs should cover proper lock washer selection, installation sequences, torque application techniques, and inspection criteria. Near-miss reporting systems help identify unsafe practices before they result in injuries. Organizations committed to safety culture should include lock washer handling in their job hazard analyses and standard operating procedures, particularly for maintenance personnel who frequently work with these components.

Suggested read: Wash Assist: Transform Your Laundry Experience with Smart Technology

Future Trends in Washer Lock Washer Technology

Smart fastener systems represent an emerging technology that may transform how industries approach fastener locking. Researchers are developing washers with embedded sensors that monitor bolt tension in real-time, transmitting data wirelessly to maintenance systems. These systems can detect gradual loosening before it causes failure, enabling predictive maintenance strategies that prevent unplanned downtime. While currently cost-prohibitive for most applications at $50-200 per sensor-equipped washer, prices are expected to decline as production volumes increase. Initial deployments focus on critical infrastructure including bridges, wind turbines, and industrial equipment where fastener failure consequences justify the investment.

Advanced materials including shape-memory alloys and composite materials are being investigated for next-generation lock washers. Shape-memory alloys like nitinol can be designed to apply increasing force as temperature rises, potentially maintaining optimal preload across wide temperature ranges. Composite materials offer the potential for customized spring rates, corrosion resistance, and electrical properties impossible with metallic washers. However, these materials face significant barriers to adoption including high costs, limited manufacturing capabilities, and lack of long-term performance data. The military and aerospace sectors will likely pioneer these advanced materials in applications where performance requirements justify premium costs.

Manufacturing innovations including additive manufacturing (3D printing) may enable customized lock washer designs optimized for specific applications. Currently, lock washers are produced almost exclusively through stamping, drawing, and forming processes that require expensive tooling making small quantities economical only for standard designs. Additive manufacturing could enable engineers to create lock washers with custom tooth patterns, spring rates, and geometries tailored to unique requirements without tooling investment. As metal 3D printing technology matures and costs decline, this capability may transform how engineers approach fastener locking in specialized applications. The wave car wash sector and other industries with custom equipment needs may particularly benefit from this flexibility.

Suggested read: Unimac Washer: Everything You Need to Know Before Buying

Frequently Asked Questions About Washer Lock Washers

What is the difference between a washer and a lock washer?

A standard flat washer distributes load across a bearing surface and protects the substrate from damage during fastener installation, but provides no resistance to loosening. A washer lock washer actively prevents fastener loosening through spring action, friction, or mechanical bite into mating surfaces, maintaining bolt tension under vibration and dynamic loads.

Can you reuse lock washers?

Reusability of lock washers depends on the type and application. Split lock washers should never be reused as they permanently deform during installation, losing their spring action. Tooth lock washers may be reused if teeth haven’t been completely flattened, though most quality standards recommend replacement. Wave washers and Belleville washers can typically be reused multiple times if they haven’t been compressed beyond their elastic limit, making them cost-effective for maintenance applications requiring periodic disassembly.

Do I need a flat washer with a lock washer?

Using a flat washer with a washer lock washer depends on the bearing surface and loading conditions. If the bearing surface is soft (wood, plastic, soft metals) or irregular, place a flat washer between the surface and lock washer to distribute load and prevent surface damage. The lock washer should always be positioned directly under the rotating element (bolt head or nut) to resist loosening. In applications with hard, smooth bearing surfaces, a flat washer is typically unnecessary and adds cost without performance benefit.

Which side of the lock washer faces up?

For split lock washers, installation orientation has minimal impact—either direction functions similarly. For Belleville washers, orientation is critical—the concave side typically faces the bolt head or nut, while the convex side bears against the joint surface. Installing Belleville washers backwards creates instability and prevents proper function. Tooth lock washers should be installed with teeth facing the bearing surface they will grip, not against the fastener head where they serve no purpose.

What grade of bolt requires lock washers?

Lock washer requirements depend on application conditions rather than bolt grade. Grade 8 and higher strength bolts generate higher clamping forces that can better resist loosening, but still require lock washers in vibration-prone applications. Lower-grade bolts in stable environments may not need lock washers. Engineers should evaluate vibration levels, consequences of fastener loosening, and accessibility for maintenance when determining lock washer requirements rather than relying solely on bolt grade as a criterion.

Are lock washers necessary with Loctite?

Using both washer lock washers and thread-locking compound provides redundant locking mechanisms that some critical applications require. However, for most applications, either a quality lock washer or appropriate thread-locking compound sufficiently prevents loosening. The combination offers advantages when maintenance accessibility is limited or failure consequences are severe. Thread-locking compounds provide superior vibration resistance but require proper surface preparation and curing time, while lock washers offer immediate locking action and visible verification of installation.

How do you measure a lock washer?

Lock washer dimensions are specified by inner diameter (ID), outer diameter (OD), and thickness. Measure inner diameter at the smallest opening that must clear the fastener shaft—for split lock washers, measure the diameter of the circle formed by the helix, not across the gap. Outer diameter is measured at the maximum width. Thickness for split lock washers is measured in the free, uncompressed state. Always reference dimensional standards like ASME B18.21.1 when ordering to ensure proper fit with fastener sizes.

What is the torque specification for lock washers?

Torque specifications for assemblies with washer lock washers typically require 10-20% more torque than identical assemblies with flat washers to achieve the same bolt preload due to additional friction. Consult fastener manufacturer specifications for the specific bolt grade, size, and lubrication condition. The lock washer itself doesn’t have a torque specification—rather, the assembly torque must be sufficient to compress the lock washer and achieve target bolt tension while avoiding over-torque that would permanently flatten the washer or strip threads.

Suggested read: Sultan Wash: The Ultimate Solution for Commercial Laundry Excellence

Additional Resources for Washer Lock Washers

For more information about washer lock washers, consult these authoritative sources:

- ASME B18.21.1: Standard for lock washer dimensions and specifications

- DIN 127: European standard for spring lock washers

- Industrial Fasteners Institute: Technical bulletins on proper lock washer selection

- American Society of Mechanical Engineers: Engineering standards and best practices

- NASA Technical Standards: Guidelines for fastener locking in critical applications

Ready to secure your assemblies with the right lock washers? Browse our comprehensive selection of washer lock washers including split lock, tooth lock, wave, and Belleville washers in all standard sizes and materials. Contact our technical support team for application-specific recommendations that ensure your fasteners stay tight under the most demanding conditions.

Citation: Information in this article is based on industry standards including ASME B18.21.1, DIN 127, and research from the Industrial Fasteners Institute. Performance data comes from published testing by NASA, automotive industry studies, and independent fastener laboratories. Material specifications reference ASTM standards and manufacturer technical documentation. For specific applications, always consult with qualified engineers and follow applicable industry standards for your region and industry sector.